TITAN AF sash components for ALU16

To achieve more with fewer components, quality is required. With TITAN, this is invested in unique product details such as the tried and tested comfort mushroom cam and the click-on coupling feature with fine toothing. But it also shows in every work step that is simplified or even omitted, thanks to TITAN. The clever system concept tightens your logistics and will lead you more quickly to success.

Sets new comfort and security standards with ease.

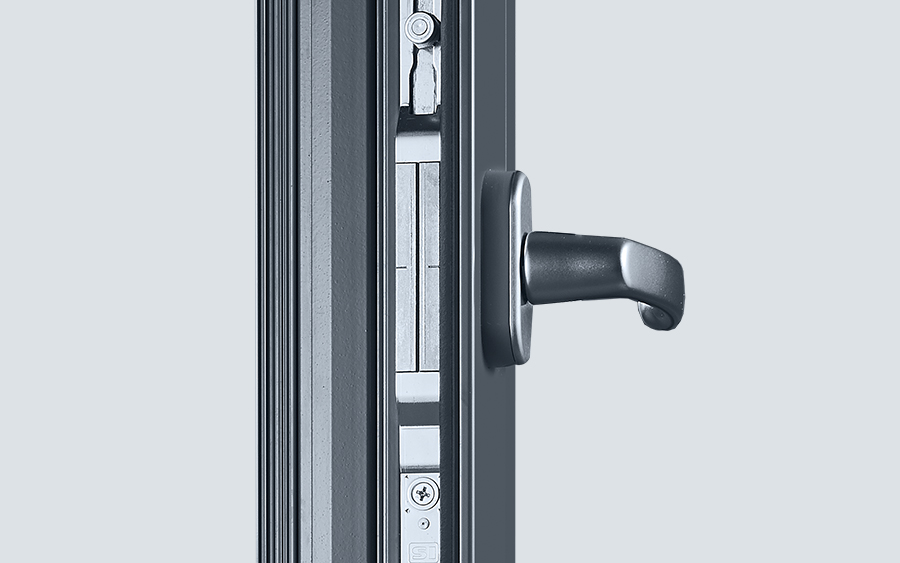

Modern TITAN gears set new standards with ease. In interaction with TITAN comfort mushroom cams they are the pivotal point for lasting high ease of use and consistent burglar resistance, but also the key to considerably greater efficiency. Because all components can be screwed into place perfectly and automatically due to their tolerance-insensitive clamping and then remain precisely and firmly seated for the long term.

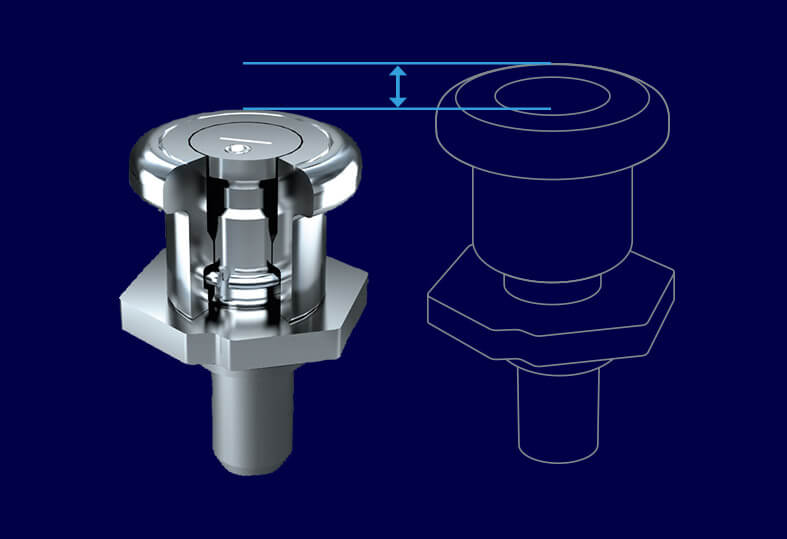

TITAN comfort mushroom cam

Automatic tolerance compensation.

- Continuous height adjustment: equalises air-gap tolerances and independently changes framework conditions, such as temperature fluctuation, therefore simplifying installation

- Maximum ease of use due to an optimally adjusted, smooth-running and durable locking system at all times

- Effective system setup with TITAN comfort mushroom cam: Fewer components and less warehousing for solutions up to RC2 and more

- High intruder resistance can be achieved

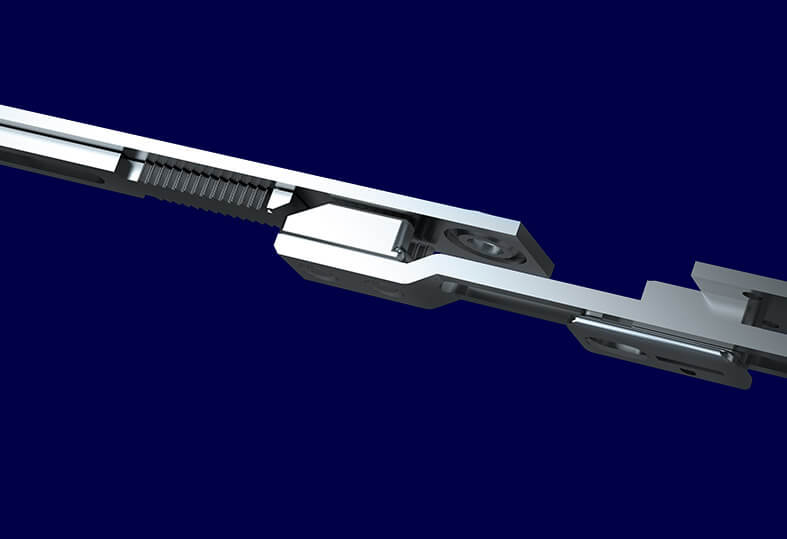

One component – wide range of benefits.

The AF corner drive can be used for all sash sizes, combines several functions in one single component and provides more ease of use together with minimum warehousing. Opening, tilting and closing is especially smooth-running because the sash is lifted early and cushioned to allow it to slide gently into the frame.

1. Tilt lock

2. Locking part

3. Sash lifter

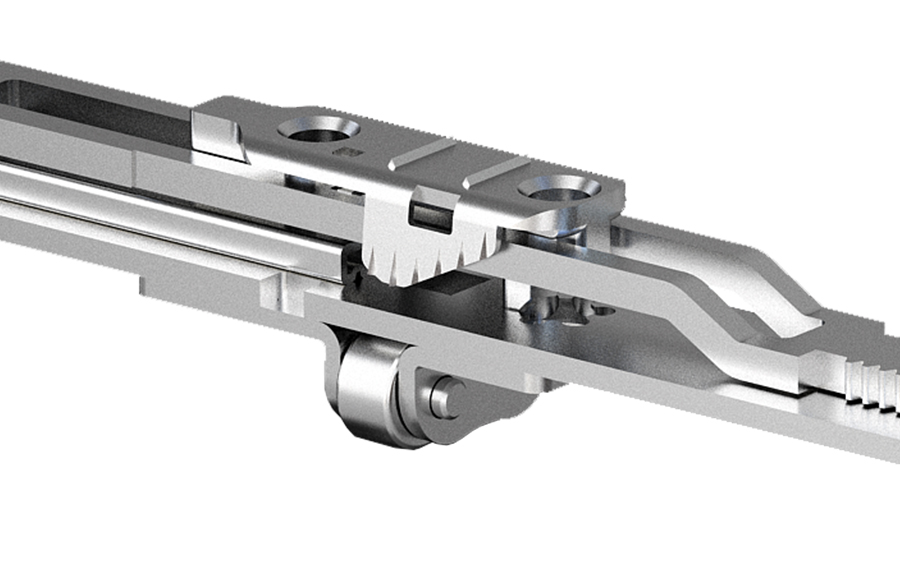

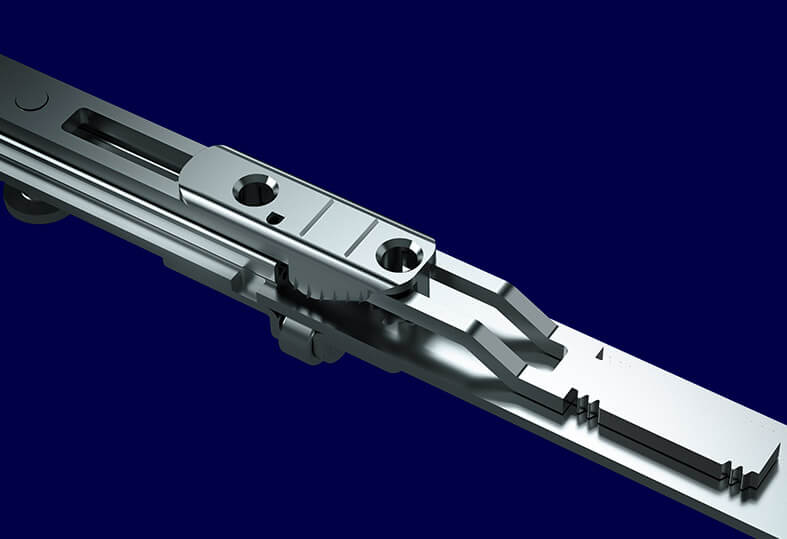

Click-on coupling feature

High precision fine toothing.

Reduces the assembly and installation time by enabling a particularly easy and secure joining of the components – with less "play" and loss of stroke. RC1 and RC2 versions can be achieved without additional cutting processes.

Clamping

Insensitive to tolerance and automatically screwable.

Effortlessly automated screwing is possible due to the reliable clamping of all components. Permanently secured positioning of hardware components is guaranteed.

Draws better, brakes more gently.

- Larger tolerances thanks to the smaller stay thickness

- Optimal tilt stay lead-in in order to close wide windows effortlessly, too

- More load-bearing capacity and comfort with minimum wear: High-quality PVC slider and serial friction bushing for gentle sliding into the tilt position

- Integrated anti-slam device in tilt position, which also cushions the stop

- Shift interlock in tilt position prevents mishandling